Packaging

Ashmore Manufacturing specialise in creating bespoke plastic packaging for a wide range of industries. From blister packaging and clamshell packaging, through to plastic trays and food grade standard containers – whatever your requirements, we can help.

With almost 30 years’ experience, our staff are highly skilled in providing clients with exceptional thermoformed food packaging as well as non-food packaging. All packaging is produced in-house to not only ensure high standards, but to allow us to price our services significantly lower than our competitors. That’s why we work with some of the biggest leading retailers and supermarkets today including Tesco, Sainsburys, John Lewis, Harrods and Selfridges.

Choose ashmore manufacturing

For your plastic packaging

Any Quantity

We offer small runs starting from 1,000 – perfect for getting that new product on the market without having cash tied up in stock.

All Designs

Clamshell, blister packaging, plastic trays, or something completely new – whatever you need, we can deliver.

Save Money

Our unique pick ‘n’ mix production system allows for multiple tooling combinations on the same run which saves customers £000’s.

Bespoke Packaging Examples

We have provided packaging for a whole range of industries. Here is just a small sample of the types of bespoke packaging we have produced.

Examples

- Macaron packaging

- Sushi packaging

- Fast food and single use packaging

- Fish packaging

- Fruit and nut packaging

- Cheese packaging

- Heat sealed packaging

Examples

- Pharmaceutical packaging

- Cosmetic packaging

- Automotive parts packaging

- Machine part packaging

- Transit trays

- Garden products

Call our team to find out more - 01722 697584

Bespoke Packaging Made Easy

Here is the typical process that customers go through for their bespoke packaging production. But we pride ourselves on being completely flexible so if you need only one of these services, that’s fine too.

- PACKAGING DESIGN

- Packaging Prototyping

- Packaging Tool Making

- Multi-Tooling

- Packaging Production

PACKAGING DESIGN

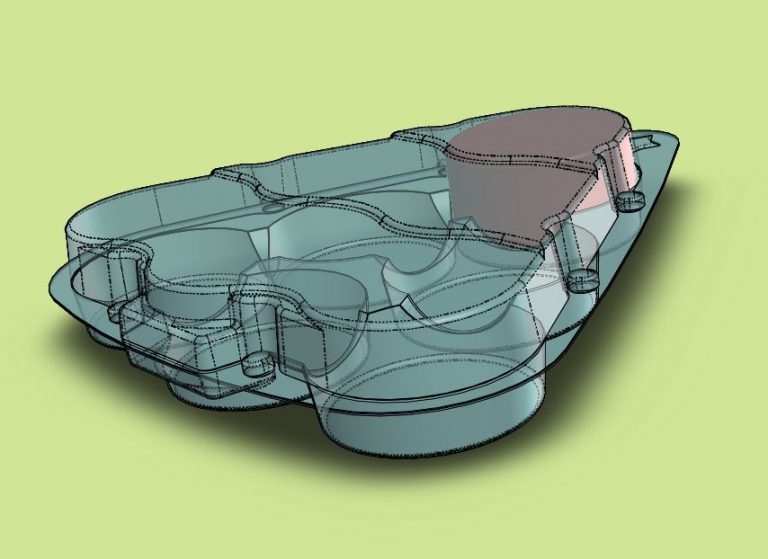

Nothing is more important than getting your design right. Starting your project with our in-house design software is the first step in turning your ideas into reality.

Product packaging design can be produced in several formats:

- Sketches / concepts

- 2D technical drawings

- Drawings for CAD

- Concept drawings

- 3D photo realistic graphic images

Packaging Prototyping

Prototyping is an important part of the process to ensure that all design elements are incorporated, and work as intended. We have the skills to produce highly engineered 3D prototypes by machine or by hand, which offers a quality finish and will perform as a completed manufactured product.

Our Modela Pro ll MDX 540 precision milling machine produces high quality items using a wide variety of materials. Some examples of the prototypes we can create include:

- Silicone tooling

- Model board tooling

- Metal and resin casting

- Foam prototype

Packaging Tool Making

Once the prototyping has been signed off, we can create a tool to use in the thermoforming and rotational moulding processes. We make all our own tools in-house using the combination of CAD and our computerised milling machine, which greatly reduces production time and saves you money.

Multi-Tooling

We know that changes in demand can cause havoc with supplies. At Ashmore Manufacturing we have put together a unique Pick ‘n’ Mix production system that eradicates these problems forever. It is an interchangeable system that allows multiple combinations of trays to be produced. You can choose up to six different products in the same production run – meaning the cost is reduced and you only produce the packaging you need. If you have products that are more popular than others, we can make more of those inserts and less of others, offering you complete flexibility.

Using this tooling method, we have saved our customers £10,000’s on tooling costs for new products. We can honestly say we don’t know of any other company who does this.

Packaging Production

Once the tool is complete, the production of the packaging can begin. Using our thermoforming machines, we heat and mould sheets of plastic on to the tool to create your custom packaging.

But our services do not end there – we really can provide the whole package (excuse the pun!). We offer a range of roller press cutting and edge folding services, if they are required, as well as printed cardboard wraps or boxes to compliment your plastic packaging.

Do you need the packaging to be in line with your green credentials? Perhaps you are trying to be more environmentally friendly? We can provide a range of options for recyclable and compostable materials for your packaging. See our bioplastics page for more information or contact us for free advice.